A product comes to life trough Electronics.

Electric power comes from the grid, induction, solar and/or a battery which, if included, needs to be charged[Charging Circuit]. Power is needed in different proportions (Current, Voltage), the responsibility of a Power Supply Unit[PSU]. Sensors can be monitored for logging and actuating. These sensors are influenced by one or more forms of: Contact (e.g. Buttons), Resistance, Capacity, Magnetism, Acceleration, Force, Induction, Light, Temperature, Pressure and Radiation. When these conditions relate calibration becomes a challenge. Memory is needed for logging data or ultimately communication with a central database. Communication can go wireless, trough copper or fiber. Protocols have to be followed for both ends to understand and process the information. As feedback to the user indicators can light up, display or print information, make sound and/or give haptic feedback. To make a move actuators turn electricity into magnetism or heat. Since these demand higher power than control signals switching or amplification is needed. The brain of it all is either a Single Board PC or Microcontroller that needs to be programmed, or an FPGA that needs structuring.

Engeen can help you to convert your ideas for an electronic product into a functional specification. According to these Engeen carries out:

- Component Selection

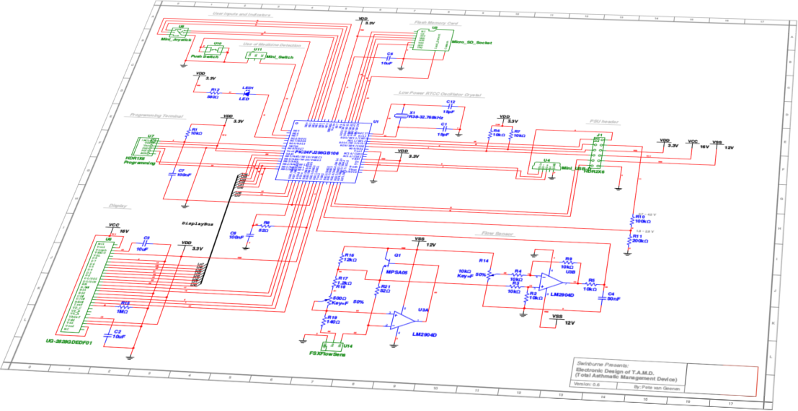

- Schematics

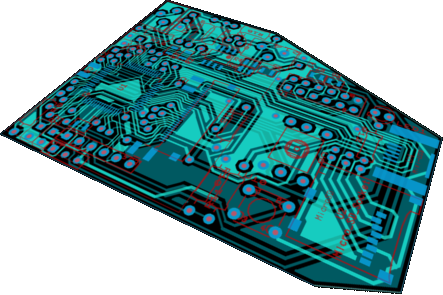

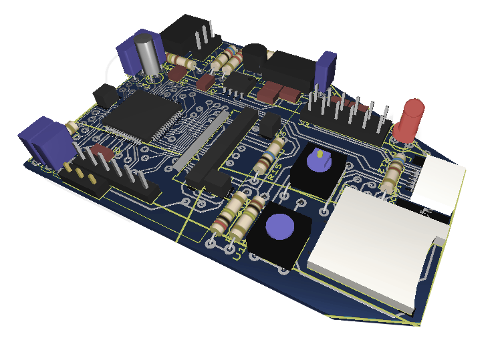

- PCB Design

- Controller Programming (Microchip, Arduino, Atmel, ST)

Advice is given on outsourcing production, qualification and testing. These services are offered as part of a turnkey project, which means the customer (you) will own the design.